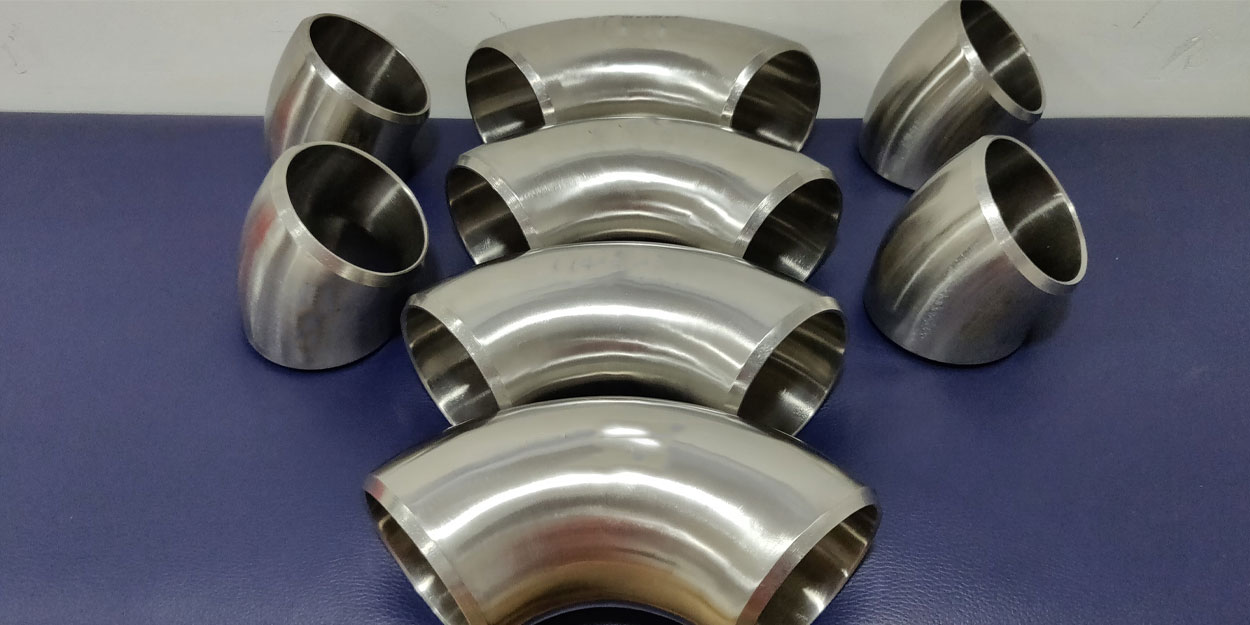

Buttweld Elbow

- Products

- Buttweld Fitting

- Buttweld Elbow

Buttweld Elbow

A butt-welded elbow is a type of pipe fitting used to change the direction of flow in piping systems, commonly found in industrial applications involving oil, gas, water, and chemical processing. It is designed to be welded to the ends of pipes, providing a strong and leak-proof joint. Butt-welded elbows are available in different angles, typically 45°, 90°, and 180°, to allow for various directional changes in the pipeline. They are manufactured from materials such as carbon steel, stainless steel, and alloy steel, depending on the application's pressure, temperature, and corrosion requirements. These fittings come in long radius (LR) and short radius (SR) versions, where long radius elbows have a center-to-end distance 1.5 times the pipe diameter, offering smoother flow, while short radius elbows are more compact and used in tight spaces. Butt-welded elbows conform to international standards such as ASME B16.9 and are preferred for high-pressure and high-temperature applications due to their durability and seamless integration into piping systems.

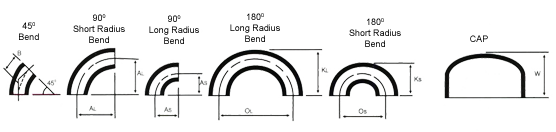

Based on the angle of bend, butt-welded elbows are classified into three main types: 45-degree, 90-degree, and 180-degree elbows. These elbows are used to change the direction of flow in a piping system, depending on the design requirements.

A 45-degree elbow is used when a slight change in direction is needed, allowing for a smoother flow with minimal turbulence. It is often used in systems where gradual redirection is essential to reduce pressure loss.

The 90-degree elbow is the most commonly used type, designed to change the direction of flow at a right angle. It is widely used in various piping layouts and is suitable for both horizontal and vertical connections.

The 180-degree elbow, also known as a return bend, is used to completely reverse the direction of flow in the system. It is commonly found in heating loops, coils, and piping systems that require a U-turn in direction. The selection of elbow angle depends on the layout, space, and flow characteristics required in the pipeline.

Pipe Elbow Material Grades

| Stainless Steel Elbow | ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L |

| Carbon Steel Elbow | ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. |

| Low Temperature Carbon Steel Elbow | ASTM A420 WPL3, A420 WPL6 |

| Alloy Steel Elbow | ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 |

| Duplex Steel Elbow | ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Werkstoff No. 1.4462 |

| Nickel Alloy Elbow | ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ) |

Dimensions

| Nom. Pipe Size | O.D. | 45° Bend | 90° Bend Long RAD | 90° Bend Short RAD | 180° Bend Long RAD | 180° Bend Short RAD | Thickness t | ||||||

| IN | MM | D | B | AL | AS | OL | KL | OS | KS | SCH 10 | SCH 40 | SCH 80 | CAPS E |

| 1/2 | 15 | 21.30 | 16 | 38 | 76 | 49 | 2.11 | 2.77 | 3.73 | 25.0 | |||

| 3/4 | 20 | 26.67 | 11 | 29 | 57 | 43 | 2.11 | 2.87 | 3.91 | 25.0 | |||

| 1 | 25 | 33.40 | 22 | 38 | 25 | 76 | 56 | 51 | 41 | 2.77 | 3.38 | 4.55 | 38.0 |

| 1 1/4 | 32 | 42.20 | 25 | 48 | 32 | 95 | 70 | 64 | 52 | 2.77 | 3.56 | 4.85 | 38.0 |

| 1 1/2 | 40 | 48.30 | 29 | 57 | 38 | 114 | 83 | 76 | 62 | 2.77 | 3.68 | 5.08 | 38.0 |

| 2 | 50 | 60.30 | 35 | 76 | 51 | 152 | 106 | 102 | 81 | 2.77 | 3.9 | 5.55 | 38.0 |

| 2 1/2 | 65 | 73.00 | 44 | 95 | 64 | 191 | 132 | 127 | 100 | 3.05 | 5.16 | 7.01 | 38.0 |

| 3 | 80 | 88.90 | 51 | 114 | 76 | 229 | 159 | 152 | 121 | 3.05 | 5.49 | 7.62 | 51.0 |

| 4 | 100 | 114.30 | 64 | 152 | 102 | 305 | 210 | 203 | 159 | 3.05 | 6.02 | 8.55 | 64.0 |

| 5 | 125 | 141.30 | 79 | 190 | 127 | 381 | 262 | 254 | 197 | 340 | 6.55 | 9.53 | 76.0 |

| 6 | 150 | 168.30 | 95 | 229 | 152 | 457 | 313 | 305 | 237 | 3.40 | 7.11 | 10.97 | 89.0 |

| 8 | 200 | 219.10 | 127 | 305 | 203 | 610 | 414 | 406 | 313 | 3.76 | 8.18 | 12.7 | 102.0 |

| 10 | 250 | 273.00 | 159 | 381 | 254 | 762 | 518 | 508 | 391 | 4.19 | 9.27 | 15.09 | 127.0 |

| 12 | 300 | 323.90 | 190 | 457 | 305 | 914 | 619 | 610 | 467 | 4.57 | 10.31 | 17.48 | 152.0 |

| 14 | 350 | 355.60 | 222 | 533 | 356 | 1067 | 711 | 711 | 533 | 4.78 | 11.13 | 19.05 | 165.0 |

| 16 | 400 | 406.40 | 254 | 610 | 406 | 1219 | 813 | 813 | 610 | 4.78 | 12.70 | 21.44 | 178.0 |

| 18 | 450 | 457.20 | 286 | 686 | 457 | 1372 | 914 | 914 | 686 | 4.78 | 14.27 | 23.83 | 203.0 |

| 20 | 500 | 508.00 | 318 | 762 | 508 | 1524 | 1016 | 1016 | 762 | 5.54 | 15.09 | 26.19 | 229.0 |

| 24 | 600 | 609.60 | 381 | 914 | 610 | 1829 | 1219 | 1219 | 914 | 6.35 | 17.48 | 30.96 | 267.0 |

45° Long Radius elbow

90° Short Radius elbow

90° Short Radius elbow

90° Short Radius elbow

90° Short Radius elbow

90° Short Radius elbow

90° Short Radius elbow

90° Short Radius elbow

90° Short Radius elbow

90° Short Radius elbow

90° Short Radius elbow

90° Short Radius elbow

90° Short Radius elbow

90° Short Radius elbow

90° Short Radius elbow

90° Short Radius elbow

90° Short Radius elbow

180° Long Radius elbow

SA 420 WPL6, ELBOW